DTF Printing: Revolutionising Textiles in South Africa

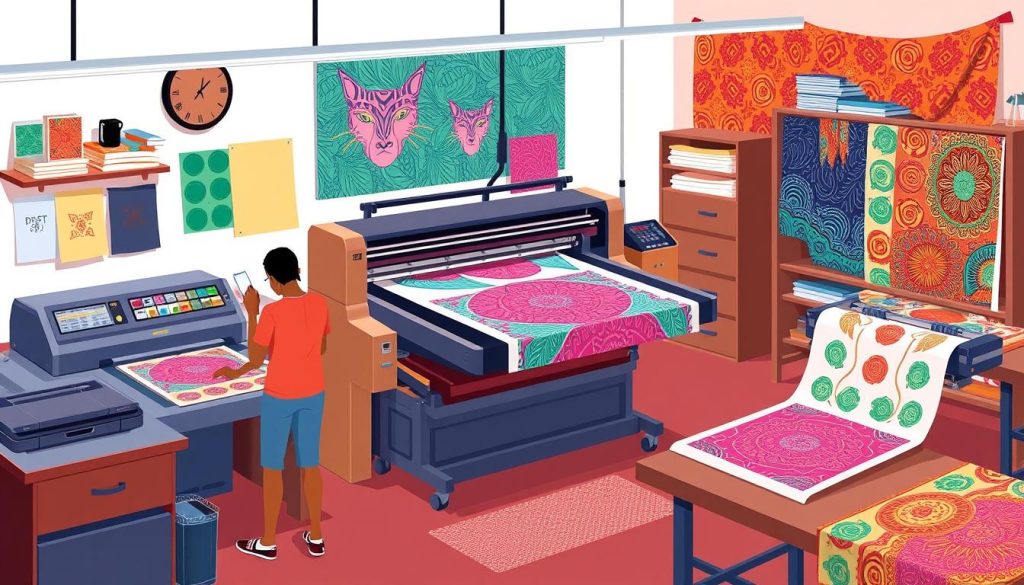

DTF printing, or Direct to Film printing, is changing the textile world in South Africa. It brings new levels of versatility, bright colours, and lasting quality. It works on many fabrics like cotton, polyester, and blends.

This method prints designs on a special film first. Then, it transfers them to the fabric using heat. This way, DTF printing beats old methods in quality.

DTF printing is great for small orders because it saves money. It uses just the right amount of film, cutting down on waste. It’s also better for the planet, needing less water and energy than old ways.

As more people want unique items, DTF printing lets businesses meet this demand. They can keep quality high while making customers happy.

Advantages of DTF Printing for Businesses

DTF printing is great for businesses wanting to grow. It’s affordable and efficient. This makes it perfect for both big and small companies.

| Advantage | Description |

|---|---|

| Cost-effectiveness | DTF printing is cheaper than some methods. A full kit costs under £1,500. This makes it easy for any business to start. |

| Versatility | DTF printing works on many fabrics. This means businesses can make products for different markets. |

| Small batch production | DTF printing is great for making small batches. This saves money and lets businesses try new things fast. |

Using DTF printing can help businesses grow. It lets them make more products and earn more money. As more people want custom items, DTF printing is a smart choice.

The DTF Printing Process

The process starts with printing a mirrored image on a special PET film, about 0.75mm thick. There are two types of films based on temperature: cold-peel and hot-peel. After printing, a white powder called Direct to Film printing powder is applied.

This powder acts as an adhesive, sticking the colours to the film. The film is then cured and transferred to fabric using heat. This way, the design sticks to the fabric without needing any special treatment.

DTF printers use CMYK settings and multiple ink tanks for the best results. They have Cyan, Yellow, Magenta, White, and Black inks. Specialised software is needed to manage colours and ink levels.

DTF printers don’t use rollers, which makes prints look better. This reduces sliding issues and ensures high-quality prints.

Comparing DTF to Other Printing Methods

DTF is different from screen printing and sublimation printing. Screen printing needs a lot of setup for each colour. It’s not good for small batches or designs with many colours.

Sublimation printing works well on light-coloured fabrics and polyester. But DTF printing can be used on many fabric types and colours, including dark ones. It’s also cheaper than other methods, making it great for businesses of all sizes.

| Printing Method | Setup Cost | Suitable Fabrics | Print Quality |

|---|---|---|---|

| DTF Printing | Low | Cotton, Polyester, Silk, Linen | High |

| Screen Printing | High | Cotton, Polyester, Blends | Medium to High |

| Sublimation Printing | Medium | Polyester, Light-coloured fabrics | High |

DTF Printing: A Game-Changer for the Textile Industry

DTF printing has changed the textile industry in big ways. It brings new levels of quality, cost-effectiveness, and creativity. This technology lets businesses be more productive and creative, helping them stay competitive.

DTF printing works with many materials like cotton, polyester, and leather. This makes it very versatile in textile printing.

Embracing DTF Printing for Your Business Success

In South Africa, it’s key for business owners to keep up with new printing tech. DTF printing is a big leap forward, offering great flexibility, cost savings, and top-notch print quality. It lets you explore new ideas and improve your products and customer service.

At Waxed Branding, we help you find the best printing solution. Our team knows about dye sublimation, direct-to-textile, and DTF printing. We guide you to expand your product range and serve more customers.

DTF printing is changing the textile game in South Africa. It’s more eco-friendly and flexible than old methods. It can print many colours at once and makes vibrant, detailed prints on different fabrics. This makes DTF printing perfect for staying ahead in today’s market.

Getting top-notch DTF printing gear is crucial for quality and efficiency. The right DTF printer and expert help can boost your business. Start using DTF printing to reach new success levels.